Investigating the Link Between Advanced Technologies and Workplace Security Measures

The New Era of Workplace Safety: A Technological Journey

The way we safeguard ourselves at work is undergoing a radical transformation, thanks to cutting-edge technology. AI-powered risk detection and real-time sensors are revolutionizing safety practices, quickening like never before. But are these advancements tackling the right issues or just adding new ones? Many workplaces now rely on automation, yet what happens when these systems fail? Can innovation truly shield workers without rethinking what remains on the ground?

Let's explore how technology and workplace safety intersect in intricate ways.

A Peek into the Frontiers of Risk Prevention

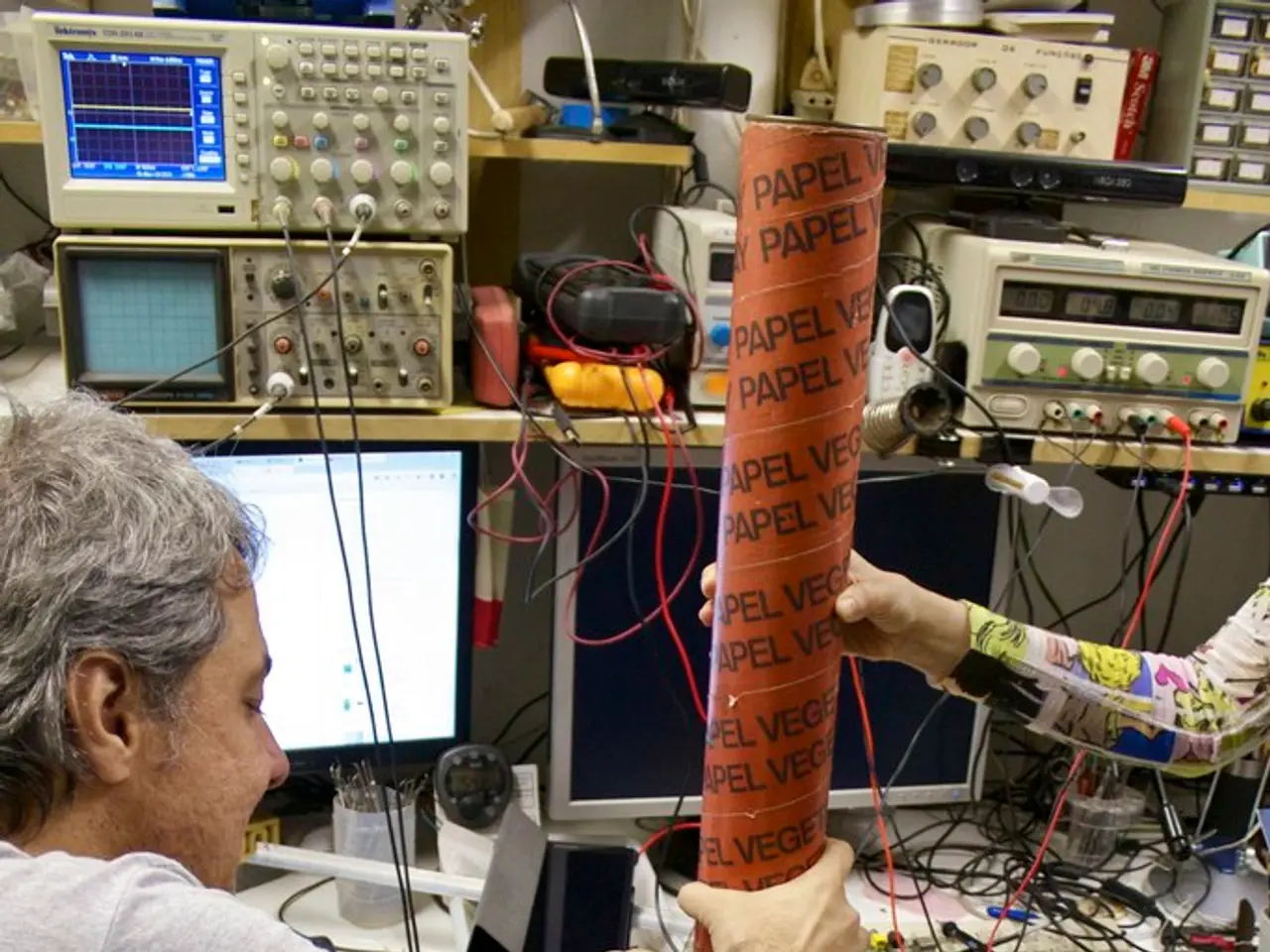

Modern digital tools are playing a pivotal role in reducing safety risks before they become problems. Wearable devices now monitor posture, stress, and movement in real-time, while smart sensors keep an eye on air quality and temperature shifts in factories.

Studies, such as those by ScienceDirect, show the potential of low-cost sensors for monitoring air quality in factories. These sensors link to the Internet of Things (IoT) systems, offering real-time environmental data for better insights. This technology is becoming indispensable for boosting safety and operational efficiency in industrial settings.

The alerts provided by these sensors help prevent fatigue, chemical exposure, and sudden equipment failure. Digital systems allow for faster emergency responses when conditions take a turn for the worse. These systems also collect valuable data for improving workplace design and hazard planning.

However, constant employee tracking raises fundamental privacy and transparency concerns. It's important that workers understand their data's use and daily protection, ensuring that safety tools respect personal boundaries.

When Sensors Fail

Sensor malfunctions can give a false sense of security, exposing workers to hidden hazards. Emergency protocols must guide responses to sensor failures using manual checks and human judgment. Reliable backup systems and traditional tools are necessary when digital monitoring proves unreliable or shuts down abruptly.

Automation's Ambivalent Impact on Dangerous Work

Automation helps minimize human exposure to risky or physically demanding tasks. Robots safely handle hazardous chemicals and operate in unstable environments. A 2025 study, published on ResearchGate, highlights how robots are transforming hazardous waste cleanup and disaster response.

Using AI and sensors, these autonomous machines execute dangerous tasks with precision, managing everything from oil spills to unstable soil without endangering humans. This shift leads to lower injury rates, improved productivity, and enhanced morale.

However, automation may diminish crucial hands-on experience among workers. Some systems still require human oversight to prevent severe malfunctions or overlooks. If an automated tool malfunctions, employees must react promptly and confidently.

Addressing Ethical Concerns

Deploying robots without defined accountability creates confusion when failures occur. Transparent, traceable autonomous decisions backed by clear oversight are necessary to ensure safety. Ethical frameworks demand that human operators stay responsible for outcomes affecting workers' well-being.

Rethinking Legacy Materials in a Modern Tech Ecosystem

While digital safety systems are more advanced than ever, harmful materials remain in use. Smart monitors can detect airborne toxins, but they don't replace the source. In factories, aging insulation, and materials with asbestos or silica continue to pose threats. Technology may alert workers faster, but alerts aren't enough when outdated substances persist.

Take, for example, the aftermath of AFFF foam use in firefighting. Despite its long history, AFFF contains compounds linked to cancer, hormonal issues, and environmental harm. Exposed firefighters have taken legal action against the manufacturers of AFFF, arguing that they knew the dangers but failed to inform or replace the materials.

The AFFF foam lawsuit raises a more significant issue: high-tech tools are often layered over unsafe foundations. Workplace innovation cannot rely solely on digital detection and monitoring. Real safety means eliminating hazards, not merely observing them digitally. A modern tech ecosystem must critically assess the legacy materials it's built upon.

The Promise of 3D Printing

3D printing allows for the creation of safe, custom parts to replace high-risk materials used in outdated systems. Facilities can design alternatives that perform better while reducing exposure to toxic chemicals and dust. This approach also lowers long-term liability and improves equipment safety and sustainability.

The Ethics of AI-Driven Decisions

AI is helping identify risks faster than traditional methods ever could. AI algorithms can detect fatigue patterns early or machine stress indicators, scanning hundreds of variables for quick safety recommendations. But, relying purely on AI removes essential human judgment and interpretation.

Data quality and algorithm bias may lead to inaccurate safety alerts. When biased models shape safety protocols, they can expose workers to avoidable hazards. IBM recommends that human oversight remains crucial for validating AI predictions and decisions. Transparent communication is key to building trust and fostering informed safety discussions at work.

When AI Systems Use Outdated Data

AI requires a wide range of data inputs to interpret workplace safety needs effectively. Contextual training must embrace human behavior, environmental changes, and non-standard scenarios across industries. Regular retraining with updated incident reports keeps AI systems responsive to emerging workplace risks.

Empowering the Workforce for a Safer Digital Tomorrow

Advanced safety tools are only useful when employees know how to utilize them. Training needs to encompass digital platforms, wearable devices, and data dashboards. Clear instructions help employees respond to alerts efficiently and effectively. Organizations must also encourage continuous learning as systems evolve and update.

The American Machinist claims that continuous learning is vital in manufacturing as technology swiftly transforms job requirements. Neglecting ongoing learning can lead to workers falling behind, potentially jeopardizing their career growth. This affects both employees and employers, particularly with rising costs and stagnant wages.

Workers equipped with strong digital literacy are better equipped to spot potential issues. A safe work culture thrives when communication flows freely and feedback is embraced. Employees must feel confident in suggesting improvements to existing technologies and routines. Employers should combine digital training with practical, on-the-ground safety procedures and drills. A strong safety culture hinges on education, access, and shared responsibility.

Crafting the Perfect Mix: Tech and Manual Safety Skills

Hybrid skills are essential for workers who can interpret digital alerts and apply them during real-world emergencies. Mastering both technical literacy and traditional hazard awareness in equal measure creates a balanced response. Training should encompass both areas for a truly comprehensive approach to workplace safety.

Walking this technological tightrope demands a thoughtful, wholehearted approach. Moving past detecting hazards to actively preventing them before they occur requires powerful AI tools with stringent data accuracy and privacy safeguards. Human oversight remains essential to catch what technology might miss. Replacing dangerous legacy materials is another crucial step to protect workers. Building a culture that fosters continuous learning and develops hybrid skills among employees creates a safer, more reliable workplace.

- The rise of AI-powered technology is fundamentally reshaping workplace safety, but questions linger about the efficacy of these advancements in addressing core issues.

- Modern digital tools like wearable devices and smart sensors play a vital role in reducing risks, monitoring air quality, and temperature fluctuations in industrial settings.

- Studies, such as those by ScienceDirect, underscore the potential of low-cost sensors for monitoring air quality in factories and linking to IoT systems for real-time data analysis.

- Digital systems offer alerts to prevent fatigue, chemical exposure, and sudden equipment failure, providing faster emergency responses and valuable data for improving safety and efficiency.

- Constant employee tracking raises concerns about privacy and transparency, necessitating that workers understand their data's use and daily protection, ensuring safety tools respect personal boundaries.

- Sensor malfunctions can lead to false senses of security, exposing workers to hidden hazards, requiring emergency protocols and manual checks to combat unreliable digital monitoring.

- Automation, such as robots handling hazardous chemicals and operating in unstable environments, reduces human exposure to risks and boosts productivity, but it may diminish hands-on experience among workers.

- Transparent, traceable autonomous decisions backed by clear oversight are necessary to ensure safety in the deployment of robots, addressing ethical concerns when failures occur.

- The continued use of harmful materials, despite advancements in technology, poses an ongoing challenge. Technology can detect airborne toxins but doesn't replace the need to eliminate hazardous substances.

- The use of AFFF foam in firefighting, linked to cancer, hormonal issues, and environmental harm, demonstrates that high-tech tools are often layered over unsafe foundations, necessitating a critical assessment of legacy materials.

- 3D printing offers opportunities for creating custom, safe parts, replacing high-risk materials, reducing exposure to toxic chemicals and dust, and improving equipment safety and sustainability.